3D Bio-Printing For Implant And Medical Device

3D Bio-printing has been used to print patient specific implant and device for medical use. In March 2014, surgeons in Swansea used 3D printed parts to rebuild the face of a motorcyclist who had been seriously injured in a road accident.

Successful operations include a titanium pelvic implanted into a British patient, titanium lower jaw transplanted to a Dutch patient and a plastic tracheal splint for an American infant. The hearing aid and dental industries are expected to be the biggest area of future development using the custom 3D printing technology.

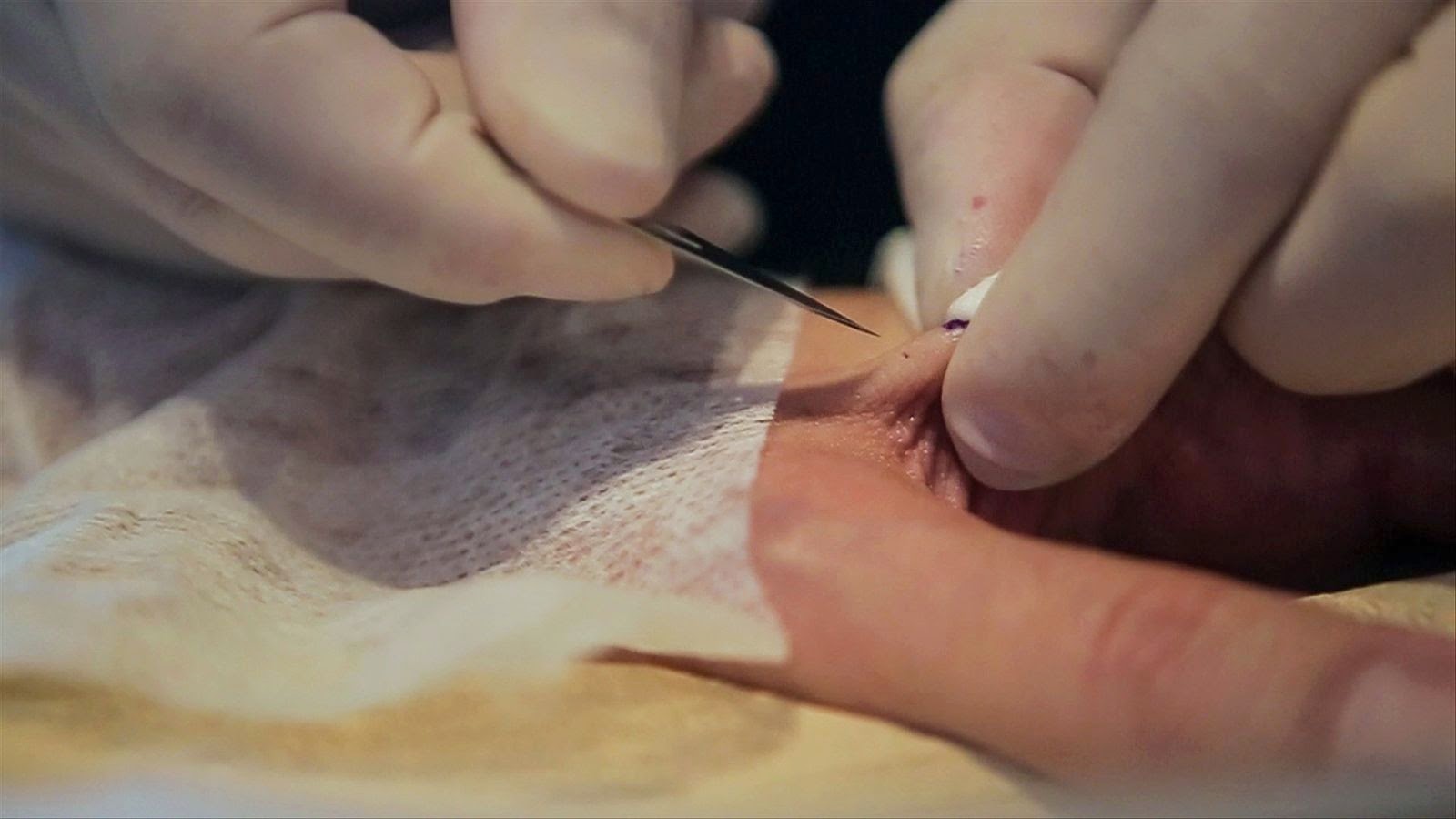

Using 3D bioprinting for fabricating biological constructs typically involves dispensing cells on a biocompatible scaffold using a successive layer-by-layer approach to generate tissue-like three-dimensional structures. Given that every tissue in the body is naturally compartmentalized of different cell types, many technologies for printing these cells vary in their ability to ensure stability and viability of the cells during the manufacturing process.

3D bio-printing is the process of generating spatially controlled cell patterns in 3D, where cell function and viability are preserved within the printed constructed. Some of the methods that are used for 3D bioprinting of cells are photolithography, magnetic bioprinting, stereolithography, and cell extrusion.

An early-stage medical laboratory and research company, called Organovo, designs and develops functional, three dimensional human tissue for medical research and therapeutic applications. The company utilizes its NovoGen MMX Bioprinter for 3D bioprinting.

Organovo anticipates that the bioprinting of human tissues will accelerate the preclinical drug testing and discovery process, enabling treatments to be created more quickly and at lower cost. Additionally, Organovo has long-term expectations that this technology could be suitable for surgical therapy and transplantation.

Organovo’s bioprinting process centers around the identification of key architectural and compositional elements of a target tissue, and the creation of a design that can be utilized by a bioprinter to generate that tissue in the laboratory environment.

Once a tissue design is established, the first step is to develop the bioprocess protocols required to generate the multi-cellular building blocks—also called bio-ink—from the cells that will be used to build the target tissue.

The bio-ink building blocks are then dispensed from a bioprinter, using a layer-by-layer approach that is scaled for the target output. Bio-inert hydrogel components may be utilized as supports, as tissues are built up vertically to achieve three-dimensionality, or as fillers to create channels or void spaces within tissues to mimic features of native tissue.

The bioprinting process can be tailored to produce tissues in a variety of formats, from micro-scale tissues contained in standard multi-well tissue culture plates, to larger structures suitable for placement onto bioreactors for biomechanical conditioning prior to use.

Comments

Post a Comment